Thermal Engineering Solutions

Chamber Furnaces for Heat Treatments of parts in batches.

Insertec also offers its own efficient Technical Assistance Service.

Sector

- Metallurgical

- Energetic (Wind, Thermal, etc.)

- Petrochemical

- Mechanic

- Tratamentist in general

Chamber Furnaces are mainly divided into:

- TMCG series, with gas heating by means of burners.

- TMCE series, with electrical heating by resistors.

The furnaces are designed both technically and dimensionally according to the type of load to be treated. Types of Heat Treatments:

- Temple

- Low and high temperature

- Annealing

- Normalized

- Austenized

- Thermal detent

- Heating prior to Forging

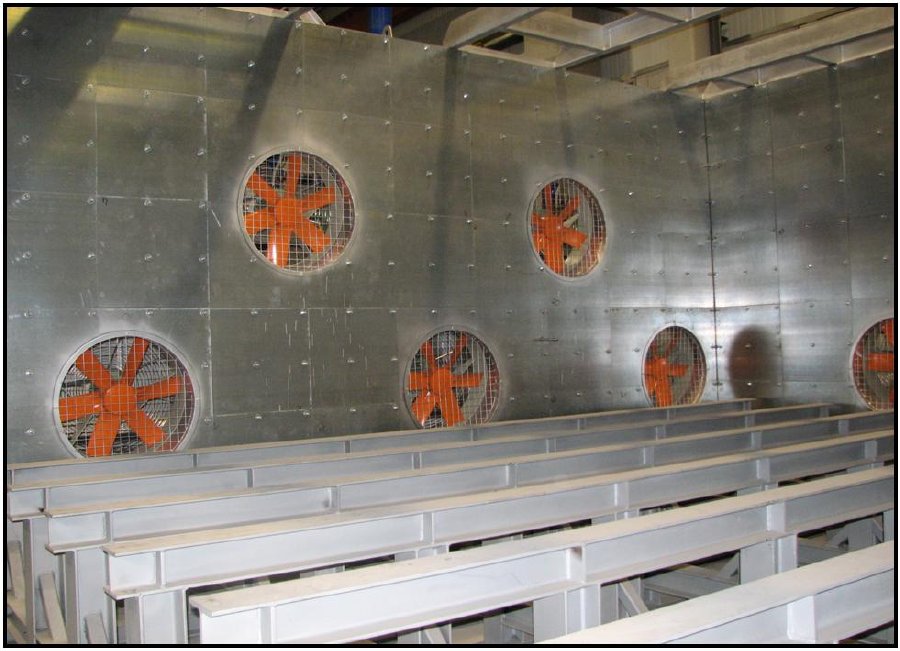

The Chamber Furnace usually has a single door, guillotine type, for loading and unloading the lots. It is equipped with a lifting gantry with hydraulic or electromechanical drive, optionally offering the door tightening system to improve its thermal seal against the front frame of the furnace chamber.

The pieces to be treated, placed on racks or inside baskets, are introduced inside the furnace by means of a Loading Machine that deposits them on the internal support of the furnace, built on the basis of pieces preformed in refractory concrete, or, in refractory steel of high quality according to the type of application.

The thermal coating of the kiln is usually done based on ceramic fiber pressed in vault, side walls and door, and refractory concrete and insulating brick in hearth according to areas.

The heating system of the furnace can be formed by:

- Gas burners of conventional type with combustion control in sequential pulsating or gas modulating mode with constant air depending on the range of process temperatures.

- Electrical resistors of plate or wire type depending on the surface density of thermal power required.

Available furnace types

Depending on the available space in the Plant and the operational needs of the Installation, other possible furnace solutions can be considered:

- Folding chamber type furnace on fixed pivot axis.

- Chamber type furnace that can be lifted by means of an incorporated lifting system or bridge-crane in the Plant.

- Chamber type furnace lift-displaceable by mobile gantry.